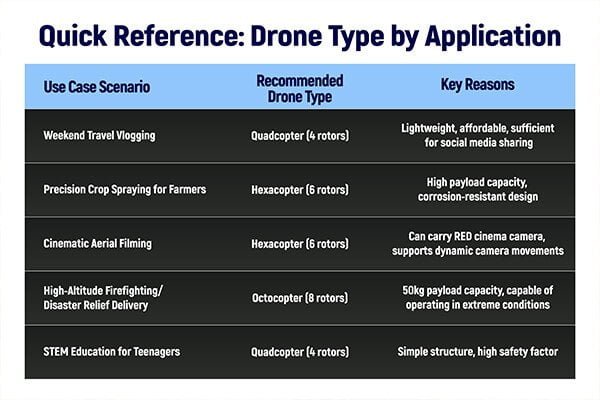

Choosing a drone platform is confusing. Picking the wrong one means risking your payload or mission. The key difference is the number of rotors, which defines everything about the drone's performance.

Multirotor is the overall category. The key difference lies in the rotor count: quadcopters (4), hexacopters (6), and octocopters (8). More rotors provide greater payload capacity and safety redundancy but also increase cost and complexity, impacting flight efficiency.

It's easy to get lost in the terminology, but the logic is straightforward. Each additional pair of motors is a trade-off between power, safety, and efficiency. As a battery manufacturer, we see firsthand how this choice impacts power requirements and mission success. I often discuss this with clients like Omar, who need to match a platform's capabilities to a specific industrial application. Let's break down exactly what each configuration offers.

What Makes a Quadcopter the Most Common Drone?

You see quadcopters everywhere, but their lack of redundancy is a concern for serious work. Is this simple design good enough? For many applications, its efficiency is unmatched.

Quadcopters are common because they are the most efficient, cost-effective, and mechanically simple design. Their high efficiency translates to longer flight times for their weight, making them ideal for consumer photography, FPV racing, and basic inspections.

A quadcopter uses four propellers, typically in an 'X' configuration, to generate lift and control. By precisely varying the speed of each motor, the flight controller directs the drone's movement. This design has become the standard for a reason: it strikes an excellent balance for a huge range of tasks.

The Upside: Efficiency and Simplicity

The biggest advantage of a four-rotor design is its efficiency. With fewer motors, propellers, and electronic speed controllers (ESCs), the overall weight is lower. This means that for a given battery, a quadcopter can generally stay in the air longer than a hexacopter or octocopter of a similar size. The mechanical simplicity also means lower manufacturing costs, fewer points of failure, and easier maintenance. This makes it the undisputed king for hobbyists, photographers, and any application where cost and flight time are more important than carrying a heavy payload.

The Downside: No Safety Net

The critical weakness of a quadcopter is its complete lack of power redundancy. If a single motor or propeller fails for any reason, the drone will lose stability and immediately fall from the sky. This makes it a high-risk choice for carrying expensive equipment or flying over sensitive areas.

Why Do Professionals Choose a Hexacopter?

You need to carry a valuable sensor and can't risk a crash. A quadcopter is too risky, but an octocopter seems too expensive and complex. What's the solution?

Professionals choose hexacopters for their key advantage: power redundancy. If one motor fails, the drone can still fly and land safely. This makes them the standard for professional aerial photography, surveying, and inspections where payload safety is critical.

A hexacopter is the professional's workhorse. By adding two extra motors and propellers, it fundamentally changes the drone's capabilities, introducing a crucial layer of safety. This is the "sweet spot" for most industrial and commercial applications. When a client needs to fly a thermal camera or a high-resolution mapping sensor, I almost always recommend a platform built on a six-rotor design. The peace of mind that redundancy provides is invaluable. The extra lift also means it can carry heavier payloads and handle windy conditions with more stability than a quadcopter.

| Feature | Quadcopter (4 Rotors) | Hexacopter (6 Rotors) |

|---|---|---|

| Power Redundancy | None | Yes (Can lose 1 motor) |

| Payload Capacity | Lower | Higher |

| Stability | Good | Better |

| Cost & Complexity | Lowest | Medium |

| Flight Efficiency | Highest | Medium |

The trade-off is a slight reduction in flight efficiency due to the extra weight and power consumption of the two additional motor systems. However, for any mission where the payload is valuable or safety is a priority, this is a trade-off worth making.

When is an Octocopter the Only Option?

You have to lift a heavy cinema camera or a large LiDAR scanner. The weight is too much for a hexacopter, and failure is absolutely not an option.

Octocopters are the only option for heavy-lift applications and missions that demand the highest level of safety. With eight rotors, they can carry cinema cameras or large industrial sensors and can safely withstand the failure of multiple motors.

An octocopter is a specialist tool built for strength and reliability. With eight powerful motors, it generates immense lift, making it the go-to platform for Hollywood-level cinematography, heavy-duty agricultural spraying, and carrying large-format survey equipment like LiDAR scanners. The primary reason for choosing an octocopter is its unparalleled safety through extreme redundancy. Depending on the design and payload, it can often withstand the failure of two or even three motors and still return to base safely. This level of security is essential when your payload is worth more than the drone itself. However, this power comes at a significant cost. Octocopters are the most expensive, complex, and least efficient of the multirotor family. Their high power consumption means shorter flight times, requiring very high-capacity, high-discharge batteries to make missions feasible.

Conclusion

The choice depends on your mission. Quadcopters offer efficiency, hexacopters provide balanced safety, and octocopters deliver maximum power. Choose the platform that matches your payload and risk tolerance.