You see the terms "Li-ion" and "Li-ion Polymer" used everywhere, but the difference is unclear. Making the wrong choice can lead to a heavy, inefficient, or poorly designed final product.

A Lithium-ion Polymer (Li-Po) battery is a specific type of Li-ion battery that uses a polymer gel electrolyte inside a flexible soft pouch instead of a liquid electrolyte in a rigid metal can. This makes it lighter and customizable.

Think of it as a specialized evolution of the standard lithium-ion battery. The core technology is the same, but this key change in construction fundamentally alters the battery's physical properties. As a manufacturer of high-performance drone batteries, this is the technology we rely on. It's not just a minor difference; it's an engineering choice that defines the performance of modern electronics.

How Does It Actually Work?

You're an engineer, so you know it's a type of Li-ion battery. But you need to understand the mechanism. How can a gel-like substance do the same job as a liquid?

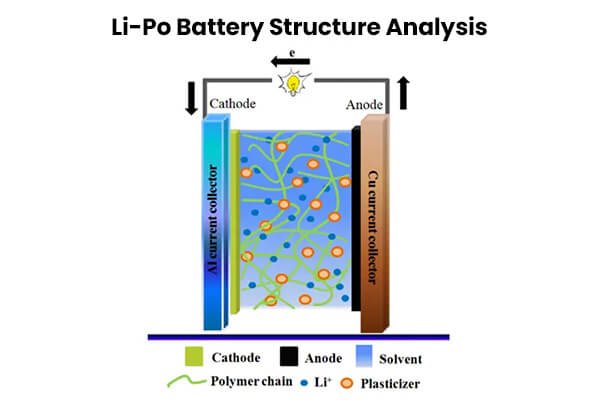

It works exactly like a standard Li-ion battery, with lithium ions moving between the anode and cathode. The only difference is the medium they travel through: a polymer gel "sponge" instead of a free-flowing liquid.

The "rocking chair" principle of ions moving back and forth is identical. The magic is in the electrolyte. Instead of filling a metal can with a liquid electrolyte, we use a polymer sheet that absorbs the electrolyte to form a stable, gel-like solid. This removes the need for a heavy, rigid container. It's important to know that most "Li-Po" batteries on the market today use this gel polymer, not a true, dry solid-state polymer. A true all-solid-state battery is the next generation of technology.

Here is a breakdown of the key structural differences:

| Component | Traditional Li-ion (e.g., 18650) | Li-ion Polymer (Li-Po) |

|---|---|---|

| Electrolyte | Liquid organic solvent | Gel-like or solid polymer |

| Casing | Rigid steel or aluminum can | Flexible aluminum-plastic pouch |

| Form Factor | Fixed cylindrical or prismatic shape | Custom, flexible, and ultra-thin |

| Weight | Heavier due to rigid can | Lighter due to soft pouch |

This difference is what allows us to deliver optimized power solutions that fit perfectly into our clients' unique designs.

Why Does This 'Pouch' Design Matter So Much?

A battery is a battery, right? Does a soft pouch instead of a metal can really make that much of a difference for a high-performance application like an industrial drone?

The pouch design is the key to creating lighter, more energy-dense, and custom-shaped batteries. For a drone, this advantage is not minor—it's the single biggest factor enabling longer flight times and higher payload capacities.

In any aerial application, power-to-weight ratio is everything. Every gram we can save on the battery is another gram you can use for your payload, or extra energy for more time in the air. The Li-Po pouch format allows us to excel in this area. It gives us the flexibility to build a battery that becomes part of your product's structure, not just a clunky component you have to design around. This is especially true for our clients in the Middle East and Russia, who need maximum efficiency for long-range surveillance or delivery missions. The ability to create a battery that matches an aerodynamic profile is a huge competitive advantage that rigid cylindrical cells simply cannot offer.

Is a Softer Battery Really Safe Enough?

You've heard the horror stories about Li-Po batteries swelling up or catching fire. A soft, flexible battery seems intuitively less safe than one housed in a hard metal can.

While no battery is completely immune to failure, the polymer electrolyte in a Li-Po reduces the risk of dangerous leakage. The main safety concerns are physical damage and swelling ("puffing"), which are managed through quality manufacturing and proper handling protocols.

The soft pouch is indeed the battery's biggest vulnerability. A puncture can lead to a short circuit and thermal runaway. This is why a good drone design must include a protective housing for the battery. The other major concern is "puffing," where gas builds up inside the pouch due to overcharging, aging, or internal faults. A swollen battery is a failed battery and must be decommissioned immediately. As a procurement manager, your most critical task for ensuring safety is to partner with a supplier that has impeccable quality control. Our factory operates under strict ISO-certified systems, and every battery pack we ship is tested to meet UN38.3, MSDS, and CE standards. This commitment to quality is the best defense against battery failure.

Conclusion

A Li-ion Polymer battery uses a polymer gel in a flexible pouch. This makes it light and customizable, perfect for drones, but it requires careful handling and high-quality manufacturing.