Choosing between Li-ion and LiPo batteries feels complex. The wrong decision can limit performance or add unnecessary weight. The answer isn't about which is better, but which is right.

In short, Lithium Polymer (LiPo) batteries are better for lightweight, high-power needs where shape is critical, like drones. Cylindrical Lithium-ion (Li-ion) batteries excel in durability, cycle life, and cost-effectiveness for applications like power tools and electric vehicles.

These two technologies are cousins, built on the same core lithium-ion chemistry. However, their physical construction and internal materials create very different strengths and weaknesses. As a manufacturer specializing in customized power solutions for drones, we work with these trade-offs every day to meet specific operational demands for clients like Omar, who need to balance performance with long-term reliability. Let's dive into what really sets them apart.

What Makes Their Physical Design So Different?

You see a hard cylinder and a soft pouch, but what does that mean? This design choice isn't just for looks; it dictates weight, energy density, and application flexibility.

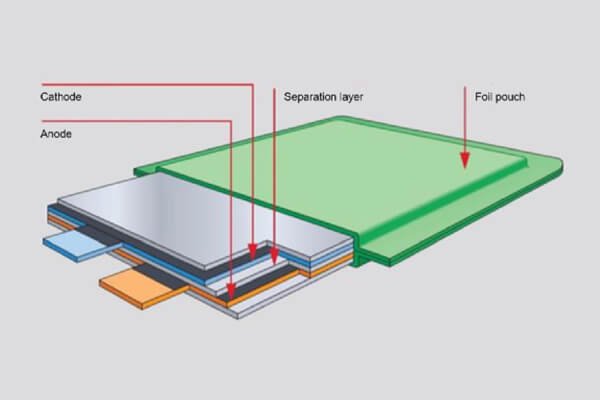

Li-ion batteries use a rigid metal case (like a steel can) filled with a liquid electrolyte. LiPo batteries use a flexible, foil-like pouch containing a polymer or gel-like electrolyte. This allows LiPo batteries to be lighter, thinner, and shaped to fit specific devices.

This fundamental difference in packaging is the most important distinction between the two. The choice of a rigid can versus a flexible pouch directly impacts what a battery can be used for. It's the starting point for every custom battery design we create.

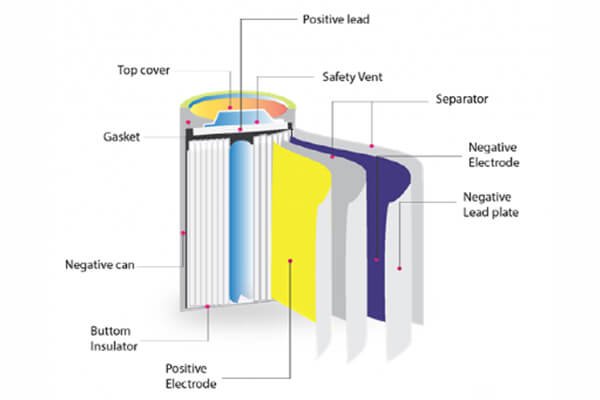

The Rigid Can: Li-ion's Strength

Standard Li-ion cells, like the famous 18650 or 21700 sizes, are built like small tin cans. Inside, the chemical layers are rolled up tightly and placed in a liquid electrolyte. This design has two main benefits: it's extremely durable and it's highly standardized, which lowers manufacturing costs. The hard metal case provides excellent protection against punctures and impacts, making it ideal for rugged applications like power tools or large battery packs in electric vehicles where individual cell safety is paramount. The downside is that you are locked into a fixed cylindrical or prismatic (rectangular box) shape.

The Flexible Pouch: LiPo's Advantage

LiPo batteries use a different approach. The internal layers are stacked in flat sheets inside a lightweight, aluminum-plastic pouch. The electrolyte is a polymer gel or solid, not a free-flowing liquid. This is a game-changer for two reasons. First, it removes the heavy metal can, making LiPo batteries significantly lighter. Second, the pouch is flexible, allowing us to create batteries in almost any thin, flat, or custom shape imaginable. This is why LiPos are the default choice for devices where every gram and millimeter counts, like high-end smartphones and, of course, industrial and FPV drones.

Which Performs Better for Demanding Applications?

Power and lifespan are what truly matter in the field. A battery that sags under load or wears out after a few cycles is a liability, not an asset.

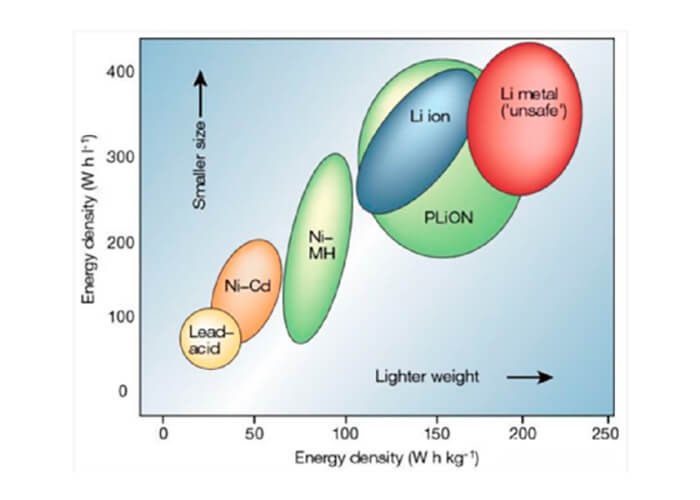

LiPo batteries generally offer superior high-rate discharge, delivering the instant power needed for drones and RC vehicles. In contrast, hard-case Li-ion cells typically provide a longer cycle life and better long-term charge retention, making them more durable for repeated, less intense use.

This is where the application becomes the deciding factor. The needs of a racing drone, which requires massive bursts of power for a few minutes, are completely different from a solar storage system that needs to charge and discharge reliably for years.

Power on Demand: The LiPo Advantage

The key performance metric for applications like drones is the discharge rate, or "C-rating." This measures how quickly a battery can safely release its energy. LiPo batteries are the undisputed champions here. Their internal structure allows for a very fast flow of ions, enabling them to deliver huge currents on demand. This is what allows a drone to punch into the sky or a racing RC car to accelerate instantly. For any application that needs extreme power in short bursts, LiPo is the superior choice.

Endurance and Cost: The Li-ion Strength

While LiPo wins on power, Li-ion often wins on longevity and cost. The mature manufacturing process and robust chemistry of cylindrical Li-ion cells mean they can typically withstand more charge and discharge cycles before their capacity starts to degrade. They are also less sensitive to minor mishandling. For a procurement manager, the total cost of ownership is key. The lower upfront cost and longer service life of standardized Li-ion cells make them the more economical choice for products that don't require the extreme discharge rates or custom shapes of LiPo.

| Feature | Li-ion Battery (Cylindrical) | LiPo Battery (Pouch) | The Winner For... |

|---|---|---|---|

| Energy Density | High | Very High | LiPo (Lightweight designs) |

| Shape Flexibility | Low (Fixed shapes) | Very High (Customizable) | LiPo (Custom devices) |

| Discharge Rate | Moderate to High | Very High | LiPo (High-power drones) |

| Cycle Life | Longer | Shorter | Li-ion (Endurance) |

| Cost | Lower | Higher | Li-ion (Standard applications) |

Conclusion

Ultimately, the best battery is the one suited for your task. Choose LiPo for lightweight power and flexible design, and Li-ion for durable, long-lasting, and cost-effective energy solutions.